How to perform a "physical examination" on a relay ceramic housing? How helium inspection technology can help auto parts manufacturers seize opportunities

Mar 08, 2025

An industry earthquake caused by a "leak"

In 2023, a well-known electric vehicle brand in Southeast Asian countries was forced to recall thousands of new cars due to the failure of the high-voltage DC relay seal - the reason was a micro-crack on the ceramic shell that was invisible to the naked eye. This lesson worth millions of dollars made the entire industry realize: "Invisible loopholes are the biggest risks."

As the new energy vehicle industry in Southeast Asian countries soars (Thailand aims to produce 725,000 electric vehicles in 2030), manufacturers of high-voltage DC relays are facing a dual challenge: not only to meet the stringent requirements of the 800V high-voltage platform, but also to control costs and seize the market. The airtightness of the ceramic shell, as the "armor" of the relay, directly determines the product life and safety.

1. Why do high-voltage DC relays have to "stick to" ceramic housings?

1. Survival rules in the high-voltage era

The 800V high-voltage platform has become the mainstream trend of electric vehicles, with larger currents and more intense heat generation. Traditional plastic housings are prone to deformation and aging, while ceramic housings have become rigid demands due to their high temperature resistance (>1000℃), strong insulation and long life.

But hidden dangers are hidden in the details: tiny pores or welding residues during the ceramic sintering process may cause hydrogen leakage, which may cause relay malfunction or battery thermal runaway.

2. The "blind spot" of traditional testing

The embarrassment of water testing: the housing needs to be dried after the immersion test, which may introduce moisture corrosion risks.

Limitations of pressure testing: only large leaks can be detected, and micro leaks of ≤10⁻⁶ mbar·l/s are helpless - this is equivalent to leaking a sesame-sized helium every year.

Industry truth: 90% of ceramic housing failure cases are due to "nano-level vulnerabilities" that traditional testing methods fail to detect.

2. Helium inspection technology: the scientific magic that makes the "invisible killer" nowhere to hide

Imagine: helium is like a group of well-trained "scouts", and the helium detector is their command center.

1. Ultra-sensitive "leak detection" principle

Molecular penetration: The diameter of helium molecules is only 0.26 nanometers, which can drill into the 0.1 micron defect of the ceramic shell.

Accurate tracking: The helium mass spectrometer is like a "gas radar", which can detect leak rates as low as 5×10⁻¹⁰ mbar·l/s (1000 times more sensitive than traditional methods).

Non-destructive testing: No need to contact liquid, avoid shell contamination, especially suitable for the cleanliness requirements of high-voltage DC relays.

Case report: After a supplier in Jakarta, Indonesia introduced an automatic helium detector, it successfully passed the German Rhine TÜV certification, won orders from European car companies, and increased its annual export volume by 200%.

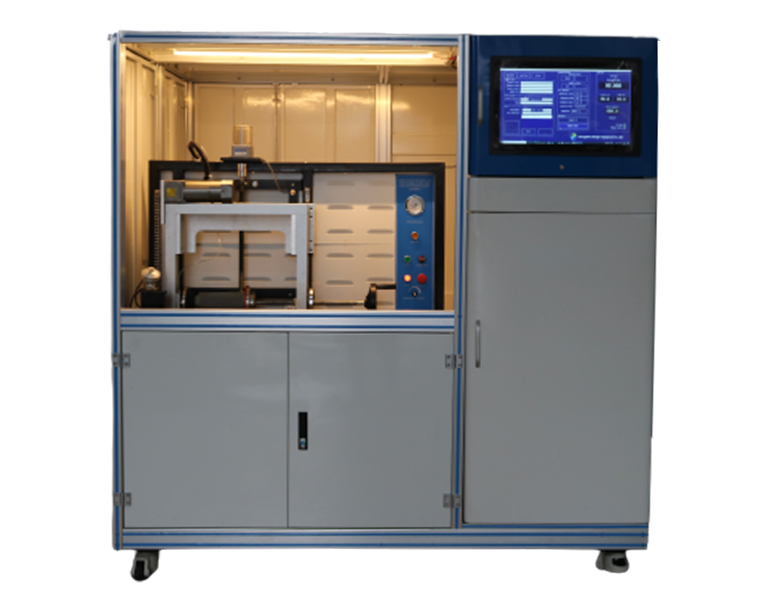

3. Automatic helium inspection machine: "efficiency-enhancing and burden-reducing magic weapon" for Southeast Asian factories

For Southeast Asian manufacturers who are sensitive to labor costs, the value of this equipment is far more than "quality inspection" - it is also an invisible engine for profit growth.

1. Speed revolution: faster than cooking a bowl of Vietnamese rice noodles

Multiple vacuum boxes are used for parallel inspection, and the time for a single piece is ≤15 seconds. More than 2,000 pieces can be inspected in 8 hours.

The code scanning traceability system automatically associates production batches, and the source of quality problems is located in 30 seconds.

2. Helium circulation: saving real money

Helium prices fluctuate violently (the increase in 2024 is more than 30%), but through the 95% recovery rate design, a single device can save about 80,000 US dollars in helium costs per year - enough to add another production line!

3. Flexible intelligent manufacturing: one machine for multiple uses

The modular design is suitable for ceramic shells of different sizes, from high-voltage DC relays for new energy vehicles to charging pile seals, and can be quickly changed in 5 minutes.

Intelligent pressure regulation (0.1-1.0MPa) matches a variety of test scenarios.

Future vision: When helium inspection machine meets AIoT

Intelligent prediction: Through machine learning, analyze historical data and reduce the defect rate.

Cross-border collaboration: Real-time remote generation of optimization solutions based on inspection data.

In the trend of "high voltage" and "fast charging" in electric vehicles, every tiny crack in the ceramic housing may cause the company's hard-earned brand reputation to collapse. An automatic helium inspection machine is not only the "gatekeeper" of quality, but also the "golden key" of the relay product line.